In the labyrinthine network of wires and connectors that constitute our modern vehicles, electrical connectors serve as vital gateways, ensuring the seamless flow of electrical signals throughout the system. Their reliable operation is paramount to the proper functioning of a multitude of essential components, including the engine, transmission, and safety features. However, the relentless onslaught of dirt, grime, and corrosion can impede these connections, causing a myriad of electrical issues ranging from intermittent malfunctions to complete system failure. Therefore, maintaining electrical connectors in pristine condition is of utmost importance to ensure the optimal performance and longevity of your vehicle.

Image: www.amazon.co.uk

In this comprehensive guide, we will delve into the intricacies of electrical connector cleaning, empowering you with the knowledge and techniques necessary to restore and maintain the integrity of these critical components. We will explore the underlying causes of connector contamination, equip you with the essential tools and materials, and provide step-by-step instructions to guide you through the cleaning process. Furthermore, we will highlight some common pitfalls to avoid and delve into the latest advancements in connector cleaning technology, ensuring that you remain at the forefront of this vital maintenance procedure. So, let us embark on a journey to unravel the secrets of electrical connector cleaning and safeguard the electrical integrity of your cherished automobile.

Understanding the Importance of Clean Electrical Connectors

Electrical connectors play an indispensable role in the intricate network of a vehicle’s electrical system, facilitating the transfer of vital signals and power throughout its electrical components. These components, ranging from the engine’s ignition system to the safety airbags, rely heavily on the uninterrupted flow of electricity to perform their intended functions. However, the accumulation of dirt, corrosion, and other contaminants on electrical connectors can disrupt this delicate balance, causing a myriad of electrical issues.

Corrosion, the result of electrochemical reactions between metal surfaces and environmental elements, poses a significant threat to electrical connectors. It forms a non-conductive layer on metal surfaces, impeding the flow of electricity and potentially leading to overheating and arcing. This can manifest as intermittent malfunctions, such as flickering lights or power windows that operate erratically, or, in severe cases, complete system failure, such as the engine failing to start or the airbags failing to deploy in the event of a collision.

Dirt and grime can also impair electrical connections, particularly in dusty or humid environments. As these contaminants accumulate on connector surfaces, they can act as insulators, preventing the proper transfer of electricity. This can lead to reduced performance, diminished fuel efficiency, and even engine misfires.

Maintaining clean electrical connectors is therefore paramount to ensuring the optimal performance and reliability of your vehicle. By regularly cleaning and inspecting these vital components, you can proactively prevent electrical issues, safeguard against costly repairs, and extend the longevity of your vehicle’s electrical system.

Identifying Contaminated Electrical Connectors

Electrical connectors can exhibit a range of symptoms when they become contaminated, providing valuable clues that can help you identify the need for cleaning. Common signs include:

- Electrical components that intermittently malfunction or fail to operate consistently, such as flickering headlights or erratic power windows

- Reduced electrical system performance, such as dim headlights or a sluggish starter motor

- Increased electrical resistance, which can manifest as overheating wires or connectors

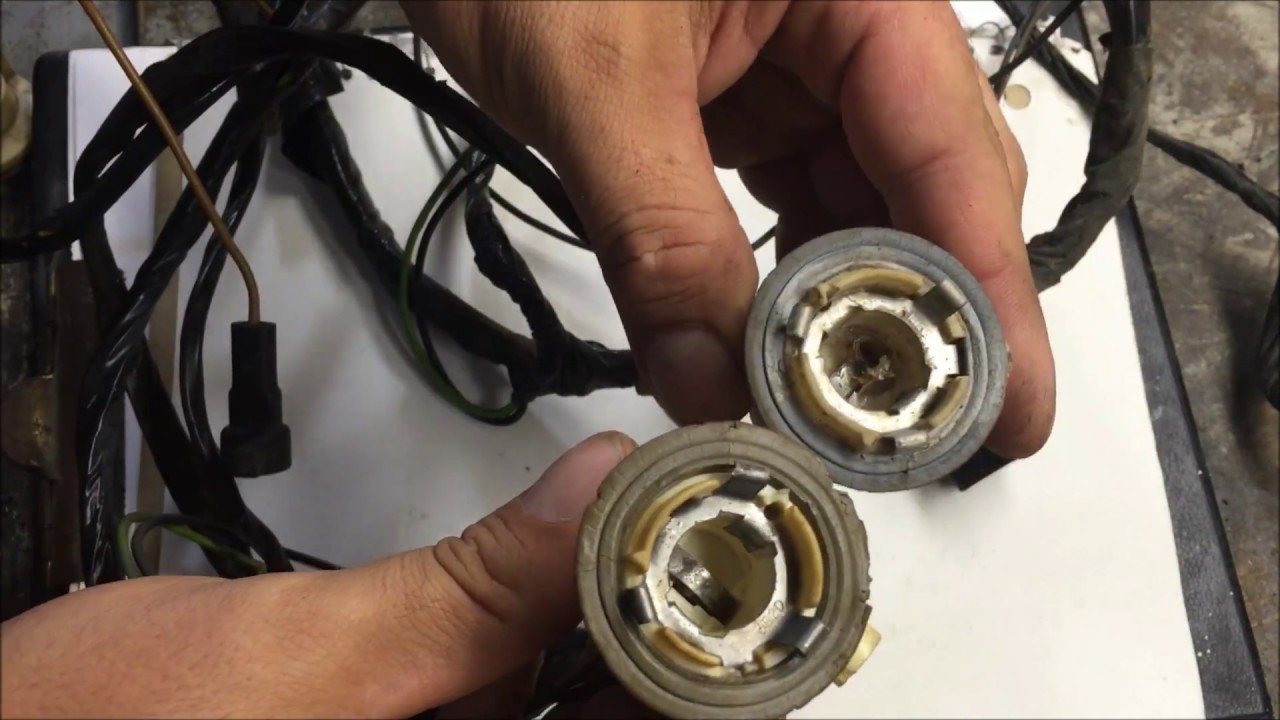

- Visible signs of corrosion, such as a greenish-white powder or a brownish-black crust on metal surfaces

If you encounter any of these symptoms, it is recommended to promptly inspect the relevant electrical connectors for signs of contamination. Dirt, grime, and corrosion can often be easily detected with a visual inspection, while more subtle contamination may require the use of a multimeter to measure electrical resistance.

Essential Tools and Materials for Electrical Connector Cleaning

Before embarking on the task of cleaning electrical connectors, it is crucial to gather the necessary tools and materials to ensure a thorough and effective job. Here is a list of essential items:

- Electrical contact cleaner: This specially formulated cleaner is designed to dissolve grease, dirt, and corrosion from electrical components without damaging delicate surfaces.

- Soft-bristled brush: A soft-bristled brush, such as a paintbrush or toothbrush, is ideal for gently removing loose dirt and grime from connector surfaces.

- Cotton swabs: Cotton swabs are useful for applying electrical contact cleaner to hard-to-reach areas and wiping away loosened contaminants.

- Soft cloth: A soft, lint-free cloth can be used to gently wipe away excess cleaner and dry the connectors after cleaning.

- Dielectric grease: Dielectric grease is a non-conductive lubricant that can be applied to electrical connectors to prevent future corrosion and ensure optimal electrical performance.

- Safety glasses: It is advisable to wear safety glasses when working with electrical components to protect your eyes from potential hazards.

Image: www.youtube.com

Step-by-Step Electrical Connector Cleaning Guide

- Safety First: Before beginning any work, disconnect the battery to ensure that the electrical system is completely de-energized. This simple step will prevent the risk of electrical shock and protect your vehicle’s electrical components from potential damage.

- Locate the Electrical Connector: Once the battery is disconnected, identify the electrical connector that requires cleaning. It is important to note that connectors can vary in design and location depending on the make and model of your vehicle. Consult your vehicle’s service manual or seek assistance from a qualified mechanic if you are unfamiliar with the location of specific connectors.

- Disconnect the Connector: Once you have located the electrical connector, carefully disconnect it by pressing on the release mechanism or unlatching the locking tab. Avoid pulling on the wires, as this can damage the connector or its wiring.

- Assess the Connector’s Condition: Before cleaning, take a moment to assess the condition of the electrical connector. Check for signs of corrosion, dirt, or other contaminants. If the connector is severely corroded or damaged, it may require replacement rather than cleaning.

- Clean the Connector Surfaces: Apply a generous amount of electrical contact cleaner to a soft-bristled brush or cotton swab. Gently scrub the connector surfaces to remove any loose dirt, grime, or corrosion. Avoid using abrasive materials or harsh chemicals, as these can damage the connector’s delicate surfaces.

- Wipe Away Excess Cleaner: Once you have thoroughly cleaned the connector surfaces, use a soft, lint-free cloth to gently wipe away any excess cleaner. This will help to prevent the formation of residue or attracting dust and dirt in the future.

- Apply Dielectric Grease: Finally, apply a thin layer of dielectric grease to the connector surfaces using a clean cotton swab or soft brush. This will help to protect the connector from future corrosion and ensure optimal electrical performance.

- Reconnect the Connector: Once the electrical connector is clean and lubricated, carefully reconnect it to its mating connector. Ensure that the connector is fully engaged and secure to prevent arcing or loose connections.

- Reconnect the Battery: After all electrical connectors have been cleaned and reconnected, reconnect the vehicle’s battery.

How To Clean Car Electrical Connectors

Common Pitfalls to Avoid

When cleaning electrical connectors, there are several common pitfalls to avoid to ensure the safety and effectiveness of the process:

- Using the Wrong Cleaning Agents: Avoid using household cleaners or solvents to clean electrical connectors, as these can damage the delicate surfaces and leave behind a residue that can impair electrical performance. Always use a specially formulated electrical contact cleaner.

- Overusing Contact Cleaner: While it is important to apply a sufficient amount of contact cleaner to dissolve contaminants, avoid overusing it, as this can leave behind a residue that can attract dirt and moisture.

- Scrubbing Too Aggressively: When scrubbing connector surfaces, use a gentle touch to avoid damaging the delicate metal surfaces. Harsh scrubbing can remove the protective coatings on the connectors, making them more susceptible to corrosion.

- Neglecting Dielectric Grease: Applying dielectric grease to electrical connectors is a crucial step in the cleaning